Kushandiswa kwealuminium extrusion mukugadzirwa kwechigadzirwa uye kugadzira kwakawedzera zvakanyanya mumakumi emakore apfuura.

Maererano neshumo ichangoburwa kubvaTechnavio, pakati pa2019-2023 kukura kwemusika wepasi rose wealuminium extrusion kuchange kuchikwira neCompound Annual Growth Rate (CAGR) ingangoita 4%.

Pamwe wakambonzwa nezve iyi nzira yekugadzira uye urikushamisika kuti chii uye kuti inoshanda sei.

Chii chinonzi Aluminium Extrusion?

Aluminium extrusion inzira iyo aruminiyamu alloy zvinhu inomanikidzwa kuburikidza nefa ine chaiyo yemuchinjikwa-chikamu chimiro.

Aluminium extrusion inogona kufananidzwa nekusvina mushonga wemazino kubva pachubhu.Gondohwe rine simba rinosunda aruminiyamu kuburikidza nefa uye rinobuda kubva paburi refa.Kana rabuda, rinobuda rakafanana nedhii uye rinodhonzwa kunze pamwe neanomhanya. Tafura.Pamwero wakakosha, maitiro ealuminium extrusion ari nyore kunzwisisa.

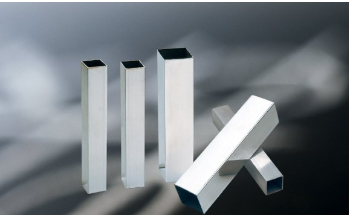

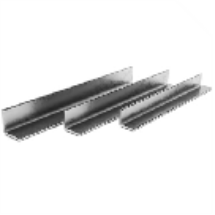

Pamusoro pane madhirowa anoshandiswa kugadzira madhiri uye pazasi pane maratidziro ezvinenge zvakapedzwa aluminium profiles.

Maumbirwo atinoona pamusoro ese ari nyore, asi extrusion process inobvumirawo kugadzirwa kwemaumbirwo akanyanya kuoma.

ZvinganiProcess?

Ngatitarisei pazasi Aluminium Art.Haisi chete mufananidzo wakanaka, unosanganisira matanho akawanda ealuminium extrusion. (Mould making-aluminium liquid-aluminium bar-aluminium extrusion-surface treatment)

1):Iyo Extrusion Die Yakagadzirirwa uye Yakaendeswa kune Extrusion Press

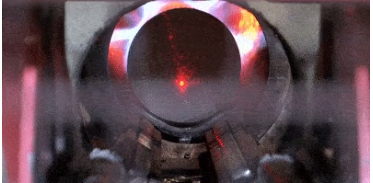

Kutanga, kufa kwakatenderedza kwakagadzirwa kubva kuH13 simbi.Kana, kana imwe yatovepo, inodhonzwa kubva mudura seyaunoona pano.

Pamberi peextrusion, kufa kunofanirwa kuve kwakapisa kusvika pakati pe450-500 madhigirii celsius kubatsira kuwedzera hupenyu hwayo uye kuve nechokwadi kunyangwe simbi inoyerera.

Kana iyo kufa ichinge yave kupisa, inogona kutakurwa muextrusion press.

2):Iyo Aluminium Billet inopiswa isati yasvika Extrusion

Tevere, yakasimba, cylindrical block yealuminium alloy, inonzi billet, inochekwa kubva padanda refu re alloy material.

Inopiswa muchoto, seyiyi, kusvika pakati pe400-500 degrees celsius.

Izvi zvinoita kuti ive inogoneka zvakakwana kune extrusion process asi isina kunyungudutswa.

3) Iyo Billet inoendeswa kune Extrusion Press

Kana iyo billet yave isati yapisa, inotamirwa nemagetsi kune extrusion press.

Isati yatakurwa pamuchina, lubricant (kana kuburitsa mumiriri) inoiswa pairi.

Mushandi wekusunungura anoshandiswawo kune gondohwe re extrusion, kudzivirira billet negondohwe kuti zvibatane.

4)Gondohwe Rinosaidzira Billet Material mumudziyo

Ikozvino, iyo billet inogoneka inotakurwa muextrusion press, uko hydraulic ram inoshandisa kusvika 15,000 matani ekumanikidza kwairi.

Sezvo gondohwe richishandisa kudzvanywa, iyo billet zvinhu inosundirwa mumudziyo weiyo extrusion press.

Izvo zvinhu zvinowedzera kuzadza madziro emudziyo

5)The Extruded Material Inobuda Kuburikidza neDie

Sezvo iyo alloy zvinhu inozadza mudziyo, iko zvino yave kudzvanywa kumusoro kune iyo extrusion die.

Nekuramba kuchiiswa dzvinyiriro pairi, iyo aluminium zvinhu haina kwekuenda kunze kwekubuda nekuvhura (ma) mufa.

Inobuda kubva pakuvhurwa kwefa muchimiro chechimiro chakazara-chakaumbwa.

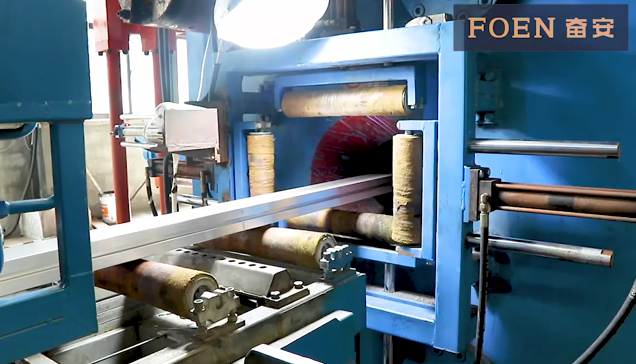

6)Extrusions inotungamirwa pamwe neiyo Runout Tafura uye Inodzimwa

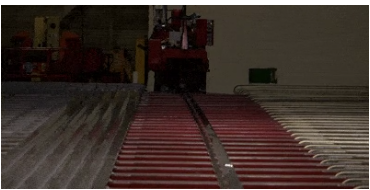

Mushure mokubuda, iyo extrusion inobatwa neanodhonza, seyaunoona pano, iyo inoitungamirira pamwe chete netafura ye runout pakukurumidza inoenderana nekubuda kwayo kubva mukudhinda.Sezvo inofamba patafura yekumhanya, purogiramu "inodzimwa, ” kana kuti zvakatonhodzwa zvakafanana nekugeza nemvura kana nemafeni pamusoro petafura.

7)Extrusions are sheared to Table Length

Kamwe extrusion inosvika pahurefu hwayo hwetafura, inochekwa nesaha inopisa kuti iparadzanise kubva kune extrusion process.

Padanho rega rega rekuita, tembiricha inoita basa rakakosha.

Kunyangwe iyo extrusion yakadzimwa mushure mekubuda mupepanhau, haisati yanyatsotonhorera.

8)Maextrusions akatonhodzwa kusvika kuTembiricha yemukamuri

Mushure mekuveura, tafura-kureba extrusions inotamiswa nemuchina kubva patafura yekumhanya kuenda patafura yekutonhodza, seyaunoona pano.Maprofiles acharamba aripo kusvika asvika mukamuri tembiricha.

Kana vangodaro, vachada kutambanudza.

Maextrusions akatonhodzwa kusvika kuTembiricha yemukamuri

Mushure mekuveura, tafura-kureba extrusions inotamiswa nemuchina kubva patafura yekumhanya kuenda patafura yekutonhodza, senge yaunoona pano.

Iwo ma profiles acharamba aripo kusvika asvika mukamuri tembiricha.

Kana vangodaro, vachada kutambanudza.

9)Extrusions inofambiswa kune iyo Stretcher uye Yakatambanudzwa muKurongeka

Kumwe kumonyoroka kwechisikigo kwakaitika mumaprofiles uye izvi zvinoda kugadziriswa.Kugadzirisa izvi, vanotakurwa kuenda kune tambo.Profile yega yega inobatwa nemagetsi kumigumo yese uye kudhonzwa kusvika yati twasa uye yaunzwa mune yakatarwa.

10)Extrusions Inotamiswa kuenda kuFish Saw uye Cheka kusvika Kureba

Netafura-kureba extrusions ikozvino yakatwasuka uye yakanyatsoshanda-yakaomeswa, inotamirwa kune tafura yesaha.

Pano, dzakachekwa kune hurefu hwagara hwataurwa, kazhinji pakati pe8 uye 21 tsoka kureba.Panguva ino, zvinhu zve extrusions zvinoenderana nekutsamwa.

Chii Chinotevera Kuitika?

Kupedzisa Kwepamusoro: Kuvandudza Chitarisiko uye Kudzivirirwa kweCorrosion

Zvikonzero zviviri zvakakosha zvekufunga nezve izvi ndezvekuti ivo vanogona kusimudzira kutaridzika kwealuminium uye zvakare inogona kuwedzera kunaka kwayo.Asi kune zvimwewo zvakanakira.

Semuyenzaniso, maitiro eanodization anokobvuta simbi inongoitika-inoitika oxide layer, inonatsiridza kusaora kwayo uye zvakare kuita kuti simbi isanyanya kupfekwa, inonatsiridza kubuda kwepasi, nekupa nzvimbo ine porous inogona kugamuchira madhayi ane mavara akasiyana.

Mamwe maitiro ekupedzisa senge pendi, poda coating, sandblasting, uye sublimation (kugadzira chimiro chehuni), inogona kuitwa zvakare.

Aluminium extrusion inzira yekugadzira zvikamu zvine chaiwo-muchinjika-chikamu profiles nekusundidzira inopisa alloy zvinhu kuburikidza nefa.Iyo Yakakosha Manufacturing process.

Nguva yekutumira: May-10-2021