Isu tose tinoziva kuti mukugadzirwa kwealuminium profiles, purofiti = kutengesa kubvisa mari yekugadzira.Iyo yose mari yealuminium profile yakakamurwa kuva yakagadziriswa mari uye inochinja mari.Fixed cost yakadai serendi yemiti, kuderera kwemichina, etc.Iyo yakagadziriswa.Uye mari yakasiyana-siyana ine zvakawanda zvekuchinja.

Panyaya yemutengo wakafanana wealuminium profil yekutengesa, iyo yakakwira mutengo wealuminium profile, iyo yakaderera purofiti.Parizvino, pasi pemamiriro ekunze akaomarara ekukwira kwemitengo yezvinhu, kukwira kwemuhoro wevashandi, kukoshesa kweRMB, kukwira kwemitengo yesimba, kuwedzera mutero wemutero uye zvichingodaro, kukwikwidza muindasitiri imwe chete kwapinda mu "white-hot" nhasi.Nguva yasvika yekudzora mari yakanaka.

Kudzora kwemitengo ndiyo kiyi iyo bhizinesi rinotungamira uye iyo core.Only nekugara uchitsvaga iyo isina simba link, migodhi yemukati inogona, inogona kushandisa nzira dzese uye nzira yekudzikisa mutengo, kutora chikamu kwakazara, kutanga kubva pane zvese, kutanga kubva pakudzikisa tsvina, aluminium. yakanaka kumisikidzwa yekudzora mutengo, inogona kunyatso kuwedzera nzvimbo yekupona kwebhizinesi, kuvandudza bhizinesi manejimendi mamiriro, kuita bhizinesi kusimudzira, uye iri munzvimbo isingapindike.

Aluminium profile cost control inobva pakukosha kweketani semutungamiri, mutengo wekutengesa wakakamurwa kuva mari yekugadzira, mari yekutenga, mari yekugadzira, mutengo wekutengesa uye mari yebasa.Nekuti kutonga kwemari kunosanganisira nzvimbo yakawanda, zvinyorwa zvakawanda.Ndichataura. nezve nzira yekuvandudza chiyero chezvigadzirwa zvakapedzwa kubva pakuona kwekugadzira kuitira kuderedza mari yekugadzira.

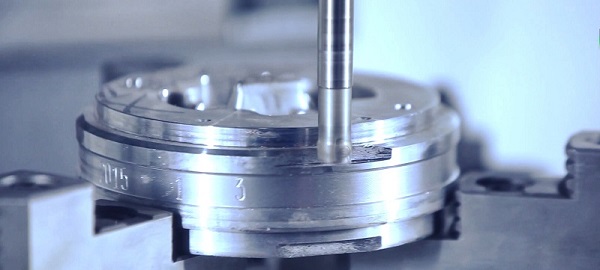

Kuburikidza nekuongorora kwedata uye maitiro, zvakaratidzwa kuti kuvandudza goho realuminium alloy profiles ndiyo imwe yedzakanyanya uye inoshanda nzira yekudzikisa mutengo wekugadzira.Tichitora extrusion workshop semuenzaniso, mutengo wekugadzirwa kwezvinhu zvealuminium uchaderedzwa ne25-30 yuan patani kana goho richiwedzerwa nechikamu chimwe chete muzana, uye chikamu chakaderedzwa ndiyo purofiti yebhizinesi.Kuvandudza extrusion. goho, basa rekugadzira nderokuderedza extrusion tsvina.

Maitiro ekuvandudza goho realuminium profiles kuderedza marara ealuminium, kuvandudza goho, uye kuderedza mutengo wekugadzira wealuminium profiles, isu takapfupikisa tsvina yakawedzera:

Iyo tsvina yealuminium extruded profiles inogona kugoverwa muzvikamu zviviri: geometric tsvina uye marara emagetsi.Geometric tsvina ibasa risingadzivisiki rekugadzirwa kwealuminium alloy profiles panguva ye extrusion.Sezvakaita extrusion yezvinhu zvakasara, kutambanudza zvigadzirwa pamagumo ose echuck, saizi yechinhu haina kukwana kureba kwehurefu hwezvinhu zvakasiiwa, cheka saizi inodiwa, iyo shunt yakasanganiswa inofa mukamuri yeshunt yeyakasara aluminium block, ingots uye zvigadzirwa zvinocheka saizi yezvinhu zvesaha-blade. kushandiswa kwealuminium machipisi uye aluminium ingots inopedzwa panguva yekuyedzwa kwekuumbwa.

Tekinoroji tsvina ndiyo tsvina inogadzirwa neusinganzwisisi tekinoroji, matambudziko emidziyo uye kusashanda zvisina kunaka kwevashandi mukuita kwealuminium alloy profil production.Kusiyana kubva kune geometrical tsvina zvigadzirwa, inogona kubudirira kukunda uye kubvisa chizvarwa chezvigadzirwa zvemarara zvehunyanzvi kuburikidza nekuvandudza kwehunyanzvi uye kusimba kwekutonga. .Technical tsvina inogona kukamurwa kuita:

Zvigadzirwa zvemarara: kupisa zvakanyanya, mhete yezviyo, zviyo zvakakasharara, shrinkage yemuswe, kuiswa kwe slag, nezvimwe.

Mechanical properties tsvina isingakodzeri: simba, kuoma kwakaderera zvikuru, kusasangana nemitemo yenyika;kana mapurasitiki akanyanya kuderera, kusakwana kunyorova hakusangane nehunyanzvi zvinodiwa.

Zvigadzirwa zvemarara zvepamhepo: maturu, mabhuru, extrusion kuputika, orenji peel, matishu clauses, mavara matema, longitudinal welding line, transverse welding line, scratch, simbi kudzvanya, nezvimwe.

Geometric dimension tsvina zvigadzirwa: wave, twist, bend, ndege clearance, saizi kunze kwekushivirira, nezvimwe.

Mwero wezvakapedzwa zvigadzirwa kupatsanurwa kwevashandi kutevedzana mwero wezvakapedzwa zvigadzirwa uye goho rakazara.

Process wapedza aruminiyamu reshiyo kazhinji rinoreva chikuru muitiro, kazhinji inobva pawekishopu sechinhu calculation.Casting process (casting workshop), extrusion process (extrusion process), oxidation coloring process (oxidation workshop), poda spraying process (spraying workshop ) .Inotsanangurwa sereshiyo yezvakagonekwa zvabuda muwekishopu kusvika pakuiswa kwezvinhu (kana semi-finished products) muwekishopu.

Mwero wezvigadzirwa zvakapedzwa une chekuita nemhando yemidziyo, ingot mhando, chimiro chechigadzirwa, kuwanda kwekuchinja kwemhando uye zvakatemwa, dhigirii repamusoro retekinoroji, bhizinesi manejimendi level uye mhando yevashandisi nezvimwe zvinhu.

Chinokosha chekuvandudza goho realuminium alloy profiles ndechekuderedza uye kubvisa tsvina.Geometric tsvina haidzivisiki, asi inogona kuderedzwa.Technical tsvina chinhu chevanhu, chinogona kubviswa pane imwe nyaya-ne-case nheyo kana kuderedzwa. .Saka, kutonga kunoshanda uye kuvandudzwa kwegoho rezvigadzirwa zve extruded zvinogona kugamuchirwa.

Kuderedza marara ejometri chinhu chakakosha chinodiwa kuti uvandudze goho rezvigadzirwa zvakapedzwa

Matanho ekudzikisa geometric tsvina

Kusarudzwa kwakarurama kweingot kureba ndiyo chiyero chikuru chekuderedza kushandiswa kwemarara.Kureba kweingot hakuverengeki mushure meextrusion, asi inoverengwa mushure mekuwedzera.

Iye zvino mabhizinesi mazhinji anoshandisa iyo refu tsvimbo inopisa shear aluminium tsvimbo yekudziya choto, kana ichienzaniswa nepfupi tsvimbo yekupisa choto, inoderedza kurasikirwa kwealuminium machipisi, nekuda kwekuchinja kwekukora kwemadziro emadziro, iyo yekukanda kureba kutonga inoshanduka uye yakarurama, inovandudza zvakanyanya. goho.Asi makambani mazhinji mukushandiswa kwevira refu tsvimbo inopisa yekuveura choto, vanoregeredza kuverenga kwekukanda kureba, uye zvakananga kupa basa kune opareta kuti adzore.Uye mushandisi kazhinji anobva pane ruzivo pasi pebhari yekutanga, cherechedza kureba kwezvinhu, kana kusiyana kwakakura, ramba uchigadzirisa, kazhinji unoda anenge 3 mbariro kuti uwane urefu hwakarurama.Mukuita, tsvina yakawanda yakagadzirwa, iyo inoderedza zvose kugadzirwa kwekugadzira uye goho.

Nzira yakarurama ndeyokuti kureba kweingot kunoverengwa nedhipatimendi rekugadzirisa maitiro panguva yekutanga kugadzirwa kwe mold.Kana iyo mold ichigadzirwa pamushini kwenguva dzakawanda, kureba kwetsvimbo yakanyorwa pane mold kadhi inowedzerwa zvishoma nezve 5-10mm, uye kureba kwechinhu kunoonekwa kana chinhu ichigadzirwa.Kugadzirisa zvakanaka kana paine misiyano.Saka tsvimbo yechipiri yakarurama kwazvo.Maererano nedzimwe dhata, goho rezvigadzirwa zvakapedzwa zvinogona kuwedzerwa nezvikamu zvina kubva muzana nekushandisa mashere akareba ekupisa, uye zvinokwanisika chose kuwedzera goho ne2 kusvika ku3 muzana muzvikamu chaizvo. production.

Mukuwedzera, nhamba yehurefu hwakatarwa kana urefu hwechigadzirwa, kuitira kuti kuve nechokwadi chekushanda kwakashata kweextrusion pasi pechigadziro che extrusion.Kana urefu hwemubhedha unotonhora hurefu hwakakwana, wedzera urefu hwehukuru hwakagadziriswa kana urefu hwezvigadzirwa. zvakanyanya sezvinobvira, kureva, iyo ingot yakareba inogona kusarudzwa.Iyowo inzira inobatsira yekuderedza chikamu chemararamiro ejometri uye kuwedzera zvibereko zvezvigadzirwa zvakapedzwa.

Matanho ekuvandudza mwero wezvigadzirwa zvakapedzwa kubva padanho rehunyanzvi

Icho chakakosha chehunyanzvi chiyero chekuvandudza mwero wezvakapedzwa zvigadzirwa kuvandudza mwero wekugadzira mold uye kugadzira uye kuderedza The Times yekuumbwa bvunzo.Kazhinji kwete iyi bvunzo mold inodhura 1-3 ingots, kuitira kuti goho rideredze 0.5-1 %, nekuda kwekugadzirwa kwefodya, yakaderera yekugadzira nhanho, zvimwe zvigadzirwa zvekugadzirisa mold, mold 3-4 nguva kana kutopfuura nguva kugadzira zvigadzirwa zvakapedzwa, zvisingaite kuderedza goho re2-5%, izvo zvisingangokonzeresa hupfumi. kurasikirwa, asi zvakare nekuda kwekudzokororwa bvunzo mold, ichawedzera kutenderera kwekugadzira.

Yemazuva ano mold zero test concept, kureva kuti, mushure mekugadzirwa kwe mold, hapana chikonzero chekuyedza mold, unogona zvakananga pamushini kugadzira zvigadzirwa zvinogoneka.Kushandisa simulation dhizaini software, finite element analysis, dhizaini inogona kupedzwa mu komputa.Inogona zvakare kuongororwa nekombuta simulation.Mold cavity processing inopedzwa mune otomatiki machining centre, kugadziridzwa kweiyo mold yese kwakanyatso kurongeka, saka mhando ye mold yakakwira zvakanyanya.Pamushini pass rate in more than than 90%.Inogona kuwedzera goho rezvigadzirwa zvakapedzwa ne2-6%.

Wedzera zvakafanira extrusion coefficient yealuminium kuti uvandudze goho

Imwe neimwe fekitori yealuminium ine nhevedzano yemichina, fekitori yega yega zvichienderana neextrusion ratio yechigadzirwa, kureba kwemubhedha unotonhora, chikamu chekunze chechigadzirwa, kureba kweiyo extrusion silinda dhayamita, kuona chigadzirwa pamushini unoenderana. kugadzirwa.Kudzidzira kwakaratidza kuti zvirevo zvakafanana zvezvigadzirwa, zvakaiswa mune akasiyana tonnage extrusion muchina kugadzirwa, nekuda kweiyo yakasiyana extrusion coefficient, chimiro chekuita kwechigadzirwa uye kugona kwekugadzira kune simba guru, goho rayo richaburitsawo misiyano. Extrusion muchina tonnage yakakura, iyo extrusion coefficient yakakura, iyo yakapedzwa chigadzirwa chiyero chakakwira, uye iyo extrusion mutengo uri pedyo.

Kuvandudza hutano hwe ingot ndiyo nheyo yekuvandudza goho

Ingots ndiyo midziyo yekugadzira extrusion.Ingots dzine chimiro chakafanana, zviyo zvakanaka, hapana slag, pores, kupatsanurwa, kuputika uye zvimwe zvikanganiso, izvo zvisingagoni kungoderedza kudzvinyirirwa kweextrusion, kuvandudza extrusion speed, uye kuvandudza kunaka kwemukati wezvigadzirwa.Uye inogona kuderedza chigadzirwa chepamusoro mabhuru, pores, scratches, cracking, pitting and other defects.Smaller slag inclusion inogona kubudiswa kuburikidza nekutsemuka kwebhandi rekushanda kwe mold, asi inokonzera pear marks pamusoro peprofile, zvichikonzera humwe hurefu hwemarara. ramba wakanamatira mumucheka webhanhire rekushanda uye haugone kubviswa, izvo zvichaita kuti mold plug kana zvigadzirwa zvinoputika uye kutsiva mold, izvo zvinokanganisa zvakanyanya goho. zvinhu.

Profile in stretching straightening, mabhizinesi mazhinji haagadziri cushion inoenderana, kunyanya mamwe mahombe akarembera profiles uye hollow profile.Nekuda kweizvozvo, deformation yemusoro nemuswe weprofile yakakurisa, uye deformation chikamu chinofanira kudimburwa kana. kuona chigadzirwa chakapedzwa.Izvi zvakakonzera kuderera kwehuwandu hwezvigadzirwa zvakapedzwa.

Iyo cushion inogona kugadzirwa nehuni yakaoma kana aluminium blocks.Iyo yakagadzirwa inoderedza ukuru hwecushion uye inowedzera kushandiswa kwayo.Kumadziro akareba uye chikamu chakavharwa cheprofile, kutwasanudza mugomba rakavharwa mukati mepadhi asiwo kuisa chigadziro chekutsigira muchikamu chemadziro.Saka, deformation in kureba kutungamira kunoderedzwa.Zvigadziriso zvinofanira kugadzirwa, kutungamirirwa uye kutungamirirwa nevashandi vanokosha.

Panguva imwecheteyo, kuitira kudzivirira chiitiko chekuti vashandi havadi kushandisa cushion nekuda kwedambudziko, tinofanira kumisa mubairo uye nzira yekuranga iyo chiyero cheyakapedzwa chigadzirwa chakabatana nemuhoro.

Simbisa manejimendi eextrusion kufa uye yepakutanga kugadzirwa rekodhi yealuminium mbiri.

Iyo mold kadhi uye yepakutanga yekugadzira rekodhi yakakosha.Iyo mold kadhi inofanirwa kukwanisa kunyatso ratidza mamiriro e nitriding ye mold, mamiriro ekuchengetedza uye mamiriro ezvinhu.Chinyorwa chepakutanga chinofanira kukwanisa kuratidza zvechokwadi kuti huremu hwekutsigira, kureba kwekukanda uye huwandu hunopa hwaro hwakavimbika hwekugadzirwa kunotevera.

Iye zvino mabhizinesi mazhinji aona zvakare komputa data manejimendi, asi kuchine nzira refu yekuenda mukushandiswa chaiko.

Deredza marara ejometri nekushandisa press-free afterextrusion

Iyo yakagadziriswa padhi inogadziriswa padanda re extrusion pasina yakasara extrusion, uye iyo miviri inoshandurwa kune imwe nhanho.Kana iyo extrusion cylinder isingadzokeri, iyo yekumanikidza pad zvakare iri nyore kuparadzanisa kubva kune ingot.Iyo inotevera ingot inobva yasundirwa zvakananga. mu extrusion cartridge.Yakawedzerwa pamwe chete neyasara yeingot yapfuura, nokudaro kudzivisa kudiwa kwekugera imwe neimwe ingot kamwe chete.Maererano nezvinodiwa zvehutano uye kurongeka kwehuwandu kuti uone nhamba yekukanda shear press.Kazhinji 40-50 zvidimbu zvinochekwa pane imwe nguva.

Gadzirisa iyo extrusion maitiro ealuminium profiles kuderedza marara ehunyanzvi

Pane zvinhu zvakawanda zvinokanganisa extrusion process of technical tsvina, iyo inovhara iyo yose extrusion kugadzirwa process.Mainly zvinosanganisira: ingot quality, process tembiricha, extrusion speed, extrusion tools, anofa, transfer loading and unloading, kuchembera kurapwa, etc. kuvandudzwa kwepamusoro, tekinoroji yekugadzira yesainzi, asiwo kwakaringana kuita kwakasimba kwemaitiro ekushanda, kunatsiridza hunyanzvi hwevashandi uye pfungwa yemutoro.

Sezvo zvichibvira kuderedza zvakasiyana-siyana zvekugadzirwa kwega-shift, zvakanakisisa kuronga marudzi 3-5 chete pakuchinja, kuvandudza kugadzirwa kweseti imwe chete ye mold. kubviswa, ndiko kunoita kuti goho riderere.

Mhedzisiro yekuumbwa pagoho inonyanya muzvikamu zviviri: bvunzo nyowani uye kushandiswa kwekugadzira mold.

Iyo nguva yakawanda iyo mold inoedzwa, iyo yakawanda yealuminium mold inotorwa, uye inoderedza goho.

Kugadzirwa kwe mold kunofanira kunyatsochengetedzwa, inonzwisisika nitriding, kugadzirisa panguva yakakodzera.Iva nechokwadi nguva imwe neimwe pamushini wakakodzera chiyero chakakwirira.Kuumbwa kwakanaka uye kusimba kwepamusoro.Kana kuchinja kwega kwega nekuda kwekugadzirisa mold kusingakodzeri, zvichiita kuti 3-4 mhando pamushini kukundikana kwekugadzirwa. , mwero wezvigadzirwa zvakapedzwa uchaderedzwa neinenge chikamu chimwe muzana.

Aluminium extrusion maturusi anosanganisira: extrusion cylinder, extrusion tsvimbo, extrusion pad, die pad, etc.Mainly kuve nechokwadi kuti extrusion cylinder, tsvimbo, mold three concentric.Secondly, kugadzirisa kunonzwisisika kweiyo extrusion cylinder, kupisa kwakarurama, kuve nechokwadi kuti kuguma pamusoro pehumburumbira inotsvedzerera.Bvisa marudzi ese e-extrusion cylinder uye ufe nechiitiko chakashata. Chenesa aruminiyamu yakasara mukati memadziro emukati e-extrusion cylinder nguva dzose, chengetedza kana rusvingo rwemukati wegomba rwakakanganisika, shandisa padhi yekufa zvakanaka, uye kuvandudza simba rekutsigira rekufa.

Extrusion tembiricha, extrusion kumhanya uye kutonhora matatu, pane chigadzirwa chimiro, mechanical properties, pamusoro pemhando ine simba guru, inokanganisawo goho.Kuwedzera, izvo zvitatu zvichakanganisa kureba kwechigadzirwa, kupisa kwetsvimbo yekukanda kwakakwira, iyo extrusion yekumhanyisa inokurumidza, chiyero chekutonhora chakaderera, chichaita kuti hurefu hwechigadzirwa mushure mekuwedzera kuwedzera, chiyero chekukura chinogona kusvika 0.5% - 1%, chinokanganisawo mutsara density yeprofile, saka iyo yakagadzikana maitiro inogona. vandudza goho.

Kuvandudza iyo inotevera extrusion maitiro kuti udzivise marara ehunyanzvi.Kuwedzera nzira inotevera yekutakura, kunyanya teerera kune chimiro cheiyo scratch scratch.

Imwe inofa porous extrusion inogona kuvandudza goho rezvakapera zvigadzirwa.

Kune zvimwe zvigadzirwa zvakakodzera kune yakawanda-yemhepo extrusion, sezvinobvira kushandisa porous extrusion, kwete chete inogona kuderedza extrusion coefficient, kuderedza uye kudzvinyirira, asiwo inogona kuvandudza goho. iyo yakapetwa kaviri gomba extrusion inogona kuwedzerwa ne3% ~ 4% pane iyo yeimwe gomba extrusion.

Extrusion speed ndiyo yakakosha process parameter mu extrusion process, iyo inoenderana nemhando yezvigadzirwa uye kugadzirwa kwakanaka.Extrusion speed haina kufanana nekuziva tembiricha yekupisa, rudzi rwe alloy alloy treatment process inogona kunyanya kusarudza tembiricha, uye the extrusion speed is a very empirical process parameter.Different alloy profiles with different sections have different extrusion speeds.Chigadzirwa chimwe chete chinokanganiswa nekushanduka kwekushisa mu extrusion process, uye extrusion speeds yakasiyana isati yasvika uye mushure me extrusion.Kuti udzore zvakanaka extrusion speed, inofanira kuva:

Neunyanzvi uye zvine hunyoro kubata huwandu hweextrusion kumhanya kweakasiyana alloys, zvikamu zvakasiyana (kusanganisira ukobvu hwemadziro), uye teerera kune kukanganiswa kweiyo extrusion kumhanya pamaprofiles ealuminium, akadai semhando yepamusoro, dhigirii rekuumbwa, nezvimwe.

Kujairika nekugona kwemidziyo yeextrusion kudzora kumhanya kweextrusion.Vamwe extruders vane nguva dzose extrusion control uye PLC control, vamwe vane PLC control chete, uye vamwe havana. pamwe nekuderedzwa zvishoma nezvishoma kwebillet mu-extrusion cylinder, extrusion pressure inoderedzwa, kubuda kwechigadzirwa kuchave kwakakurumidza uye nekukurumidza, dzimwe nguva kuita chigadzirwa mushure mekuputika.Naizvozvo, zvakakosha kugadzirisa extrusion speed.Only by kunzwisisa mamiriro emidziyo anogona iyo extrusion kumhanya kugadziridzwa zvakanaka uye kudzorwa.

Nzwisisa kukanganiswa kwezviumbwa zvakasiyana paextrusion speed.Kazhinji kutaura, extrusion speed yeflat die (solid profile) yakakwirira kudarika yekupatsanurwa kufa (hollow profile).Asi rudzi rumwe chete rwe mold, the same section shape yechigadzirwa, nekuda kwekugadzirwa uye chiyero chekugadzira chakasiyana, kukurumidza kwekuwedzera kwakasiyana.Kunyanya, chikamu chine musiyano wemadziro emadziro, kana semi-hollow profile ine kuvhura, iyo ine hukama hukuru ne mold.Chete imwe extrusion kumhanya yakagadzirwa ne mold ndiyo yakanyanya kunaka.Sipidhi inokurumidza kana kuti inononoka, uye iri nyore kugadzira kumonyoroka nekuvhura nekuvhara.

Deredza kugadzirwa kwemarara nekusimbisa kuongorora kwekutanga uye kuongorora maitiro

Iyo yekunze dimendi yearuminiyamu tsvina zvigadzirwa, senge kukora kwemadziro kunze kwekushivirira, kumonyoroka, kucheneswa kwendege, kuvhura kana kuvhara, nezvimwewo, zvinonyanya kuenderana netsvimbo yekutanga mushure mekuyedzwa kwekuumbwa neruoko rweanotambira mukuburitswa kwekuongorora uye yemhando yekuongorora. mukuongorora kwakaoma kudzivirira kugadzirwa kwezvinhu zvakaraswa zvakadaro.Kushivirira kwemadziro emadziro kunofanirwa kudzorwa kubva mukushivirira kwakashata, nekuti nekuenderera mberi kwekugadzirwa kwezvinhu, ukobvu hwemadziro ezvigadzirwa huchawedzera zvishoma nezvishoma nekuda kwekupfeka uye kubvaruka zvishoma nezvishoma. ye mold.Kune maprofayiri makuru emadziro, paunenge uchidhirowa uye uchitwasanudza kuti unyatsotarisisa kudhirowa, chengetedza huwandu hunonzwisisika hwekutambanudza.

Tsvina yepasi senge makwara, ganda reorenji, matishu, mavara matema, mabhubhu, kazhinji hazvisi zvese zvemudzi zvigadzirwa zvinoonekwa. Izvo zvinodikanwa kuti utarise mumwe nemumwe kuburikidza nemugadziri wemuenzi, muongorori wemhando uye maitiro ekucheka kwechigadzirwa chakapedzwa. uye pamwe chete kutarisa kubviswa kwemarara pamusoro.

Kana iyo inspector yemhando isingawani zvikwapuro patafura yekuburitsa, uye inowana mavanga pane zvakapedzwa zvigadzirwa pakuona, zvinodikanwa kuti utarise kubva pakutendeuka kwemubhedha unotonhora kuti uone kana zvimwe zvikamu zvebhandi rekutakura, digger uye zvichingodaro. dzakaoma uye dzakatanhamara, zvichikonzera mavanga.

Hunhu manejimendi manejimendi evashandi vese uye maitiro ese.Nzira imwe neimwe inofanira kuva nehutano hwakanaka, kuitira kuti kuzviongorora, kuongorora pamwe chete uye kuongorora kwakakosha kunogona kubatanidzwa, kuitira kuti ibudirire kubvisa tsvina yezvigadzirwa mu bud.Artificial control uye kuvandudza goho.

Kuburikidza nezviyero zviri pamusoro zvinogona kuderedza marara ejometri, zvinogona kuonekwa kuti kuderedzwa kwemarara ejometri chinhu chakakosha chekugadzirisa matanho emabhizinesi, ane kukosha kukuru kune zvakakosha zvehupfumi.

Kuvandudza goho realuminium extrusion billet ndeyekupedzisa uye nekuchenjerera basa rekugadzira extrusion kugadzirwa, kwete chete tekinoroji maficha anofanirwa kunge aripo, asiwo manejimendi anofanirwa kunge ari panzvimbo.Pachine nzvimbo yakawanda yeChina's aluminium profile. mabhizinesi ekuvandudza goho, goho richave risingaperi hurongwa, kuvandudza goho uye kuvandudza chigadzirwa chemhando, kubuda kwakanyatsobatanidzwa.Is an enterprise tekinoroji uye manejimendi nhanho yezvakakwana embodiment.

Kuvandudza goho reoxidized colored aluminium

Chibereko che oxidation ndicho chibereko chekugadzirwa kumwe chete, kureva, chibereko chekugadzirwa kumwe pasina rework.Zvinoenderana nemaitiro ekugadzira, mutengo weakagadziridzwazve maprofiles ndeye 3 nguva yeasina-reworked profiles, uye iyo yepamusoro yemhando yemaprofiles haigone kuvimbiswa.Ehe, mhando yezvigadzirwa zvine oxidized inotanga kubva kumusangano wekukanda.Nekuda kwezvirambidzo zvemuchadenga, inotevera ihurukuro pfupi pamusoro pezvimwe zvinhu zvinofanirwa kutariswa mune iyo oxidation yekugadzira maitiro.

Iyo screw pakati petsvimbo yakaturika uye conductive danda inofanira kugara yakasimbiswa.Tisati tasunga zvinhu, tinofanira kutanga tatarisa kana tsvimbo inorembera yakagadziriswa yakasununguka.Kana yakasununguka zvishoma, inofanira kusimbiswa munguva.Imwe ngura, tsvimbo inorembera ichava diki, inoda kuchinjwa nenguva, nokuti nzvimbo yayo inofambisa iduku, iri nyore kukonzera kupisa, panguva imwechete kusunga, kudzivirira profile inowira mukati me slot inokonzerwa nedanda, pfupi dunhu kukuvara kune magetsi.

Panguva imwecheteyo inowira muchimiro chetangi inofanira kucheneswa kunze nenguva, senge alkali yekugezesa tangi mune chimiro, ichakurumidza kuora, kuedza kwakaratidza kuti kushandiswa kwealkali kwakafanana nekugeza alkali kwe50-100. midzi yeprofile ye alkali kushandiswa.Kuwira mu tangi yemavara kana tangi yekuisa chisimbiso, nekuda kwekuora, tangi ichaunganidza nhamba yakawanda yearuminiyamu ion, inokanganisa hupenyu hwebasa remvura yetangi.

Kusunga zvinhu nearuminiyamu waya ine marudzi maviri ezvakatemwa zvakanaka, aniseed kusarudza coarse aruminiyamu waya, yepakati uye diki zvinhu zvinoshandiswa mune yakanaka aluminium waya, inogona kushandiswa 2mm uye 3mm, kana 2.2mm uye 3.2mm marudzi maviri ezvinyorwa, aruminiyamu. wire annealing hardness inotora 1/2 ~ 3/4 yakanaka.Parizvino, mabhizinesi mazhinji akashandurwa kuita jig.

Usati warembera muoxidation tangi kuti usimbise chimiro chega chega; Iyo rework zvinhu pamberi peiyo oxidation yezvinhu, kushandisa pliers kurova kumagumo kweiyo profil kuita kuti ienderere mberi kwechinhu, kuitira kuti kusangana pasina firimu, kuve nechokwadi chekufambisa kwakanaka. .

Nyora zvinhu zvakarembera muoxidation tangi uye coloring tangi conductive chigaro inofanirwa kutarisisa kurudyi, neimwe nzira inorerekera kune Yin uye Yang ruvara musiyano.

Mushure mekupera kweiyo oxidation simba rakamiswa nekufamba kwenguva, gara muoxidation tangi kwemaminetsi mashoma zvinokanganisa gomba rekuvharira, zvakare ichaita kumhanya kwekupenda; Mushure meoxidation, inosimudzwa uye yakanyungudika mumhepo kwenguva yakareba.Imwe magumo eiyo acid yekudzikisa mhinduro yakasvibiswa nekuda kwekuwedzera kwepore kweiyo oxide firimu, uye musiyano wemavara kumigumo yese iri nyore kuoneka.

Iyo pH kukosha kwematangi mana ekugezesa emvura pamberi uye mushure mekupenda tangi inofanira kuchengetedzwa yakagadzikana.Iyo pH kukosha kweakajairika mana ekugeza matangi emvura inodzorwa sezvinotevera:

Iyo pH kukosha kwekugezera kwemvura yekutanga mushure meiyo oxidation: 0.8 ~ 1.5

Iyo pH kukosha kwechipiri yekugezesa mvura mushure me oxidation: 2.5 ~ 3.5

Iyo pH kukosha kwekugezera kwemvura yekutanga mushure mekupenda: 1.5 ~ 2.5

Iyo pH kukosha kwechipiri yekugezesa tank mushure mekupenda: 3.5 ~ 5.0

Mumamiriro ezvinhu akajairika, imwe chiyero chemvura inoputika inovhurwa panguva yekugadzirwa, uye iyo inlet valve yakavharwa munguva iyo kugadzirwa kunomiswa.Haifanire kubuda kana kuwedzera mvura mutangi rose.Kana mvura ikaramba iri mutangi rekugeza rekutanga mushure mekuita oxidation kwemaminetsi mashoma, kukurumidza kwemavara kunokwidziridzwa, uye kana mvura ikaramba iri mutangi rekugeza rechipiri, ruvara ruchadzikiswa.

Pakugadzirwa kwesimbi ine mavara akajeka ekutevedzera simbi, nzira yekupenda inowanzotorwa kutanga, yozodzokera kune yakajairwa color plate.Nekuda kwekusiyana kwemavara ekutevedzera simbi coloring time control range idiki kwazvo (2 ~ 3 seconds chete) , uye kushandisa mutemo wekudzima unogona kuva ne10 ~ 15 masekondi enguva yekudzora ruvara, uye kusvava kwakabatana kunobatsirawo kune iwowo ruvara rwekumashure, yekutevedzera simbi inopera uye anopindirana mavara ruvara runoita kushanduka girinhi, uye kamwe-kamwe coloring inoita kuve mutsvuku.

Nyora zvinhu zvakarembera kubva patangi yemavara uye yekutanga tangi yekugezera mushure mekupenda mushure mekurembera usamire isina chinhu nguva yakarebesa, zvikasadaro iyo profil yepamusoro ichaonekwa ribhoni, isina kuenzana ruvara uye kupera kwemvura kwechichena chiitiko, inofanira kunge iri zvishoma pane ruvara rwe. Kugeza kunotevera nenguva, ruvara rwakarurama runofanira kunge rwuri mukugezesa kwechipiri mushure.Kazhinji kutaura, zvekutevedzera simbi zvinhu, senge musiyano template ruvara rutsvuku, zvinoratidza kuti coloring nguva haina kukwana kuti vakwanise ruvara;Kana ruvara rweyero. , yave neruvara, zvichienderana nekudzika kwemavara, unogona kusarudza kudzoreredza mutangi yemavara kana mutangi rekutanga rekugezesa mushure mekupenda.

Kuwedzera nzira yemishonga mune tangi yemavara: stannous sulfate uye nickel sulfate inofanira kunyungudutswa mutangi, uye kuwedzera kwemavara kunofanira kunyungudutswa mumvura yakachena (mvura yakachena inonyungudika).Izvo zvinofanirwa kucherechedzwa kuti iyo yakasimba yekuwedzera inogona kudururwa mushure mekunyungudika zvachose, uye iyo concentrated sulfuric acid inogona kudururwa yakananga mujairira tangi.

Iyo tembiricha, nguva uye mhando yemvura yekugeza mvura inopisa pamberi pe electrophoresis inofanira kuvimbiswa.Kana yakasara SO42- mugomba re oxide isina kushambidzwa, yellowing uye opacity yepende yefirimu inogona kuitika mushure me electrophoresis uye kubika. Mumamiriro ezvinhu akajairika, tembiricha yemvura inopisa inodzorwa pa60 ~ 70 ℃, uye kugeza kwemvura inopisa. nguva ndeye 5-10 maminitsi.

Nguva yekutumira: Mar-26-2021